INJECTION MOULDING CURTIS | PRODUCTION OF PLASTIC PRODUCTS

The CURTIS injection moulding plant offers a comprehensive service for the production of plastic parts by direct injection. We specialize in the production of plastic products with final assembly for industries such as electronics, household appliances, toys, containers for global brands. At the customer’s request, we enrich our plastic products, using dedicated dyes, adapting them to the individual needs of customers.

THE PLASTICS PROCESSING INCLUDES::

- conventional injection of plastics, such as: HIPS, PC, ABS, PC-ABS, PP, PE, etc. We are ready to make products from other materials, according to the customer’s wishes.

- injection in the technology of Heat & Cool, RICH (Rapid Injection Cooling Heating), H-Mold – all these technologies allow to obtain products with a high gloss – the so-called piano plastic)

- IML (In Mold Labeling – a method of labeling products in a form) – in individual cases, it is possible to use the technology

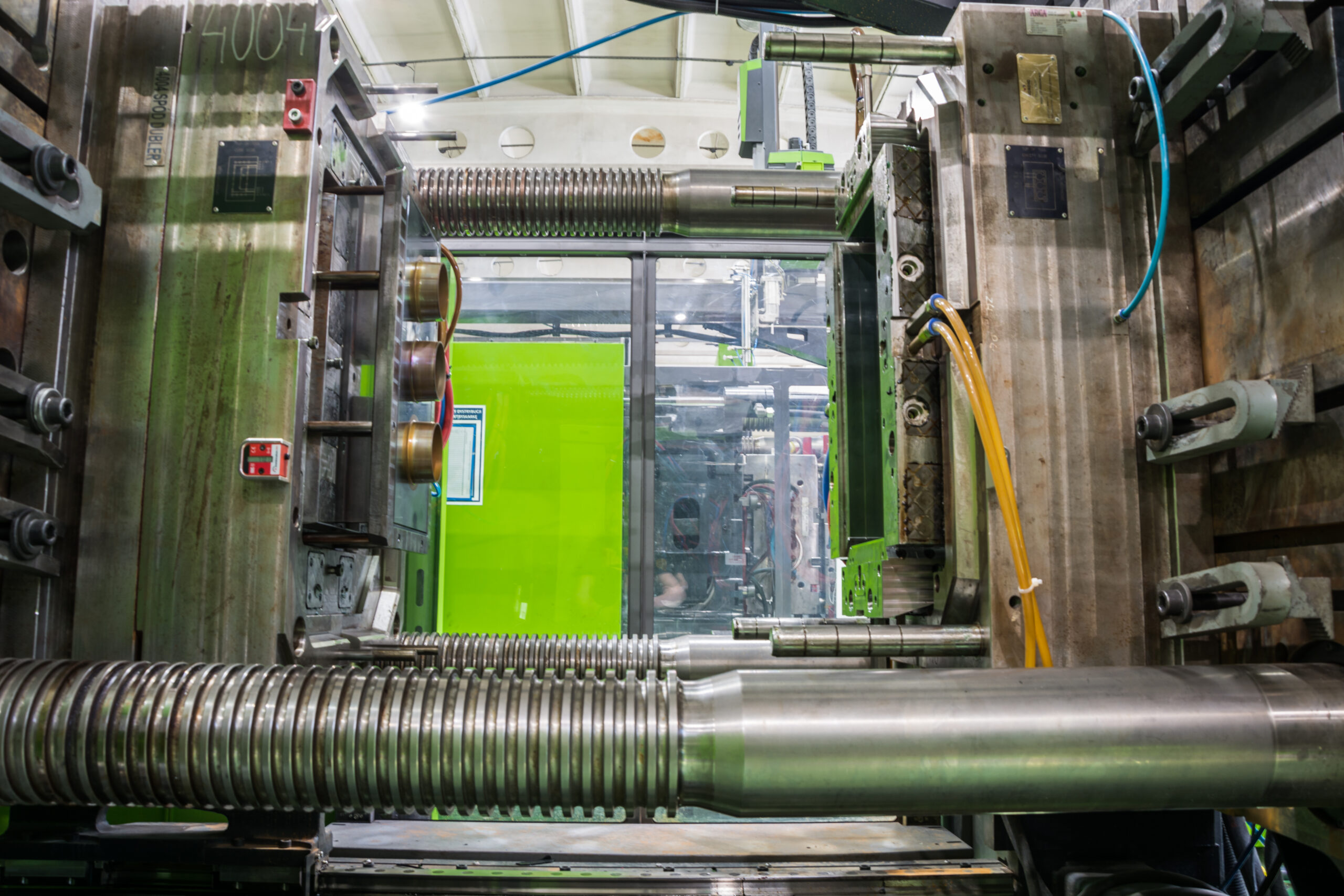

The modern machinery park located in the injection department includes 22 injection machines of renowned brands, such as: ENGEL, TEDERIC, BATTENFELD with clamping forces from 110T to 2000T. The machines are equipped with dedicated robots and belt conveyors. Our injection molding machines are connected to the central cooling system. Additionally, on the premises of the plant there are peripheral devices required for the injection process, such as driers for plastics.

MACHINE PARK

| No | Producer | Type | Screw diameter [mm] | Injection volume [cm3] | Closing force [T] | Max opening stroke [mm] | Min form height [mm] | Max form height [mm] | Distance between columns [mm] | The dimensions of the plates [mm] | Centering hole diameter FRONT [mm] | Centering hole diameter BACK [mm] | Max stroke of the ejectors [mm] | Year of production | Robot / Producer |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ENGEL | VC500/110 | Ø40 | 251 | 110 | 500 | 300 | tiebarless | 740x470 | Ø125H7 | Ø125H7 | 130 | 2006 | ENGEL | |

| 2 | KAI MING | PD 148T | Ø40 | 251 | 148 | 365 | 140 | 460 | 455x405 | 698x653 | Ø100 | Ø40 | 95 | 2008 | - |

| 3 | BATTENFELD | HM180 / 750B6P | Ø40 | 283 | 180 | 650 | 325 | 975 | 570x520 | 810x805 | Ø160H7 | Ø160H7 | 200 | 2014 | WITTMANN |

| 4 | TEDERIC | DT II 300/i1500 | Ø55 | 656 | 300 | 650 | 250 | 650 | 630x630 | 940x940 | Ø100 | Ø160 | 160 | 2018 | SWITEK |

| 5 | TEDERIC | DT III 300/i900 | Ø65 | 992 | 350 | 690 | 280 | 700 | 680x680 | 1005x1005 | Ø160 | Ø100 | 160 | 2020 | SWITEK |

| 6 | JSW | J350ADS-890H | Ø66 | 890 | 344 | 700 | 300 | 770 | 810x730 | 1165x1085 | Ø200 | Ø140 | 150 | 2019 | WEMA |

| 7 | ENGEL | VC 2550 / 350 | Ø70 | 1193 | 350 | 1300 | 300 | 1000 | tiebarless | 1200x1100 | Ø160H7 | Ø160H7 | 250 | 2005 | SWITEK |

| 8 | TEDERIC | DT III 300/i3800 | Ø80 | 2031 | 500 | 840 | 320 | 800 | 820x820 | 1205x1205 | Ø200 | Ø100 | 200 | 2019 | SWITEK |

| 9 | ENGEL | DUO 2460/500 | Ø70 | 1212 | 500 | 1300 | 250 | 800 | 910x830 | 1270x1260 | Ø200H7 | Ø200H7 | 250 | 2018 | ENGEL |

| 10 | ENGEL | CL 3550 / 650 | Ø80 | 1960 | 650 | 900 | 300 | 920 | 1025x925 | 1500x1410 | Ø200H7 | Ø200H7 | 250 | 2006 | ENGEL |

| 11 | ENGEL | CL 4550 / 650 | Ø90 | 2480 | 650 | 900 | 400 | 920 | 1025x925 | 1500x1410 | Ø200H7 | Ø200H7 | 250 | 2005 | ENGEL |

| 12 | ENGEL | DUO 5160/700 | Ø90 | 2608 | 700 | 1600 | 350 | 1050 | 1100x960 | 1510x1440 | Ø200H7 | Ø200H7 | 250 | 2018 | ENGEL |

| 13 | ENGEL | DUO 5550 / 900 | Ø80 | 2160 | 900 | 1600 | 500 | 1100 | 1170x1000 | 1550x1520 | Ø250H7 | Ø250H7 | 300 | 2013 | ENGEL |

| 14 | ENGEL | DUO 5550 / 900 | Ø90 | 2740 | 900 | 1800 | 400 | 1100 | 1170x1000 | 1650x1470 | Ø250H7 | Ø250H7 | 300 | 2006 | ENGEL |

| 15 | ENGEL | DUO 5550 / 1100 | Ø90 | 2740 | 1100 | 2000 | 400 | 1200 | 1400x1150 | 2000x1830 | Ø250H7 | Ø250H7 | 300 | 2010 | ENGEL |

| 16 | ENGEL | DUO 7050 / 1100 | Ø105 | 4160 | 1100 | 2000 | 400 | 1200 | 1400x1150 | 2000x1830 | Ø250H7 | Ø250H7 | 300 | 2006 | ENGEL |

| 17 | ENGEL | DUO 5550 / 1100 Eco | Ø90 | 2740 | 1100 | 1800 | 600 | 1200 | 1400x1150 | 1850x1810 | Ø250H7 | Ø250H7 | 300 | 2011 | ENGEL |

| 18 | ENGEL | DUO 11050/1300 | Ø120 | 6447 | 1300 | 2350 | 700 | 1400 | 1530x1275 | 2340x2040 | Ø250H7 | Ø250H7 | 300 | 2004 | ENGEL |

| 19 | ENGEL | DUO 7050 / 1500 Eco | Ø105 | 4160 | 1500 | 2350 | 700 | 1400 | 1530x1275 | 2200x1990 | Ø250H7 | Ø250H7 | 300 | 2011 | ENGEL |

| 20 | ENGEL | DUO 11050/2000 | Ø120 | 6447 | 2000 | 3000 | 800 | 1800 | 2000x1600 | 2900x2500 | Ø315H7 | Ø315H7 | 350 | 2003 | ENGEL |

| 21 | ENGEL | 250HL-2F/ES 500W (2K) | Ø60/Ø35 | 735/192 | 250 | 850 | 550 | 850 | tiebarless | 1050x900 | 2000 | ENGEL | |||

| 22 | TEDERIC | DH680/i4800 | Ø85 | 2531 | 680 | 1400 | 450 | 850 | 1100x960 | 1500x1400 | Ø250 | Ø160 | 300 | 2021 | SWITEK |

The production of plastic products takes place with the use of molds provided by the customer. We provide our clients with full service both in the field of production of plastic details and the possibility of making tests of entrusted molds.

TECHNICAL INSPECTION AND MAINTENANCE OF INJECTION MOLDS

In order to prevent breakdowns of injection molds, we regularly perform technical inspections and maintenance. The operation of transporting the injection molds to the inspections from injection molding machines is carried out by means of an overhead crane. Maintenance works include, among others:

- disassembly of molds,

- cleaning of cooling channels,

- replacement of seals in cooling channels and hydraulic systems,

- cleaning and lubrication of mold elements,

- inspection / replacement of the wear condition of mold elements,

- setting form

We clean the molds with the most effective method of cleaning with dry ice today, without the risk of leaving traces, causing abrasion and contaminating the environment with harmful substances.